The post How to Choose the Right Swimsuit Manufacturer for Your Business appeared first on Wings2fashion.

]]>Define Your Business Needs in Swimsuit Manufacturers

Understanding your specific requirements is the first step in selecting a manufacturer. Are you looking for private label swimsuit manufacturers to create a unique brand identity? Or do you need a partner that can provide a wide range of styles and sizes? Knowing your needs will help you narrow down your options effectively.

Key Considerations:

- Target Market: Determine if you will focus on swim wears for ladies or if you plan to include swimming wear for plus size customers as well.

- Style Preferences: Consider if you want to offer specific designs, such as high neck swim wear, to cater to particular market trends.

Research Swimsuit Manufacturers USA and Options

When looking for manufacturers, it’s essential to explore different types of wholesale swimsuit manufacturers. Sourcing from swimsuit manufacturers in the USA can offer numerous advantages, including faster shipping times, easier communication, and potentially higher quality standards.

Benefits of Local vs. Overseas Sourcing:

- Local Sourcing: Often results in better quality control and shorter turnaround times. Consider swimsuit manufacturers in California for their proximity and reputation.

- Overseas Manufacturing: May offer lower production costs, but be mindful of longer shipping times and potential communication barriers. Explore options like swimsuit manufacturers in India or swimsuit manufacturers in the Philippines for cost-effective solutions.

Evaluate Manufacturer Capabilities for Swimwear

Once you’ve identified potential manufacturers, assess their capabilities. Look for manufacturers with a solid track record and experience in producing swimwear.

Important Factors:

- Production Capacity: Can they handle your expected order volumes?

- Customization: Especially with private label swimsuit manufacturers, inquire about their ability to customize designs, colors, and materials to fit your brand.

Focus on Quality Assurance in Swim Wears for Ladies and Swimming Wear for Plus Size

Quality is paramount when it comes to swimwear. Customers expect durable, stylish, and comfortable products. Therefore, it’s essential to ensure that your manufacturer adheres to high-quality standards.

Quality Assurance Steps:

- Certifications: Check if the manufacturer holds relevant certifications, such as ISO or OEKO-TEX, which indicate compliance with safety and environmental standards.

- Sample Products: Request samples to evaluate the quality of materials and stitching. This is especially important when considering best swimsuit manufacturers.

Analyze Pricing and Payment Terms with Wholesale Swimsuit Manufacturers

Pricing structures can vary significantly among wholesale swimsuit manufacturers. Understanding these structures and the terms of payment is crucial for budgeting purposes.

Key Considerations:

- Minimum Order Quantities (MOQs): Be aware of the MOQ requirements, as some manufacturers may require larger orders.

- Payment Terms: Review payment options, including deposits and payment timelines, to ensure they align with your business model.

Communication and Support with Swimsuit Manufacturers

Effective communication is vital for a successful partnership. Choose a manufacturer that offers clear communication channels and responsive customer support.

Communication Tips:

- Language Proficiency: Ensure that you can effectively communicate, especially if the manufacturer is overseas.

- Customer Support: Assess their willingness to assist you throughout the production process, from design to delivery.

Read Reviews and Testimonials for Swim Wears

Before making a final decision, gather insights from other businesses that have worked with the manufacturers you’re considering. Reviews and testimonials can provide valuable information about reliability and quality.

Sources for Reviews:

- Industry Forums: Engage in discussions to find recommendations.

- Social Media: Check platforms like Instagram for feedback from other retailers.

Conclusion

Choosing the right swimsuit manufacturer is a critical step in building a successful swimwear line. By defining your needs, researching options, and evaluating capabilities, you can find a partner that aligns with your vision. Pay close attention to quality, pricing, and communication to ensure a fruitful collaboration. The right choice will not only enhance your product offerings but also contribute to the overall success of your business.

Additional Resources

- For a more comprehensive look at swimwear trends, consider exploring swimsuit manufacturers in Australia or swimsuit manufacturers in Miami.

- If you’re looking for unique styles, check out swimsuit manufacturers in NYC or swimwear manufacturers in the UK for inspiration.

For diverse offerings, don’t forget to explore unique vintage dresses manufacturers that can complement your swimwear line.

The post How to Choose the Right Swimsuit Manufacturer for Your Business appeared first on Wings2fashion.

]]>The post Top 10 Vintage Wholesale Suppliers for Unique Vintage Dresses appeared first on Wings2fashion.

]]>What Is a Vintage Dress?

A vintage dress is typically defined as clothing that is at least 20 years old, reflecting the styles and trends of its time. These dresses can range from casual wear to formal attire, and they often carry a unique story and character that modern clothing lacks. From vintage designer dresses to vintage formal dresses, there’s something for everyone in the world of vintage fashion.

Top 10 Vintage Dresses Manufacturers & Wholesale Suppliers

- Wings2Fashion

Leading the pack, Wings2Fashion specializes in supplying a vast array of vintage dresses for women. Their collection features unique vintage dresses that harmoniously blend classic aesthetics with contemporary trends. With a commitment to quality and customer service, they provide a reliable source for retailers looking to stock vintage clothing. - Vintagemaya

Located in Jaipur, Vintagemaya focuses entirely on wholesale vintage clothing and accessories. Their inventory includes vintage western dresses and A-line vintage dresses that appeal to startup retailers wanting to offer eclectic and timeless pieces. Vintagemaya ensures authenticity and quality in every item they provide. - The Vintage Street

Based in Delhi, The Vintage Street offers a comprehensive range of high-quality vintage items, including vintage formal dresses and casual wear. Their well-selected merchandise caters to boutiques and online stores, making it easy for startups to find unique pieces that resonate with their customer base. - Retro Rhythm

Retro Rhythm, headquartered in Mumbai, specializes in retro-inspired fashion items. They offer a variety of vintage dresses, accessories, and footwear, perfect for startups looking to tap into nostalgic trends. Their products evoke a sense of bygone eras while remaining stylishly relevant today. - The Vintage Nest

This Bangalore-based supplier focuses on vintage decor and furniture, but they also provide vintage dresses for women. Their collection is curated for startup retailers and interior design firms, emphasizing sustainability and craftsmanship. Each piece is designed to enhance the ambiance of any space. - Vintage Vogue

Located in Jaipur, Vintage Vogue specializes in unique vintage textiles and fabrics, catering primarily to startup fashion houses. Their offerings include various historical materials that can elevate any clothing line, making them an essential resource for those interested in vintage designer dresses. - Classic Charm

Based in Kolkata, Classic Charm is a premier wholesale destination for vintage jewelry and accessories. While they focus on accessories, their vintage pieces complement any collection of vintage dresses, providing a complete look for fashion-forward retailers. - Antique Alley

Located in Hyderabad, Antique Alley supplies antique and vintage collectibles. They offer an array of unique items that can enhance any retail collection, including vintage dresses and home decor. Their focus on individuality ensures that retailers receive unique pieces to captivate their customers. - Nostalgia Treasures

Based in Pune, Nostalgia Treasures specializes in sourcing vintage collectibles and retro memorabilia. They offer a range of nostalgic items that appeal to collectors and niche gift shops, making it easier for startups to find unique products that resonate with their target audience. - Retro Relics

Based in Chennai, Retro Relics focuses on vintage electronics and gadgets. While their primary focus is not clothing, their unique offerings can complement a fashion line, providing an interesting twist for retailers looking to attract tech-savvy customers interested in retro aesthetics.

Conclusion

The world of vintage manufacturers & wholesale suppliers offers a treasure trove of options for anyone looking to acquire unique vintage dresses. From stylish vintage formal dresses to casual vintage western dresses, these manufacturers & suppliers play a crucial role in preserving pieces of history while making them accessible to modern consumers.

For more on seasonal styles, check out our guide on 10 Top Floral Dresses For Every Woman In Summer and discover how to elevate your wardrobe with Trendy Dresses for Women. If you’re seeking tips for a chic look, explore 6 Style Tips for Classy and Unique Dressing and learn how to Stay Stylish with Trendy Dresses. Embrace the charm of vintage clothing and explore the endless possibilities it offers!

The post Top 10 Vintage Wholesale Suppliers for Unique Vintage Dresses appeared first on Wings2fashion.

]]>The post What fabric is Muslin Fabrics? appeared first on Wings2fashion.

]]>What is meant by Muslin Fabrics?

Muslin is a loosely plain-woven cotton fabric. One weft thread is woven back and forth through one warp thread in the plain weave method used to create this fabric. In the fashion industry, testing patterns before cutting and sewing the final item is the best use for muslin material. This cloth is distinguished by its clarity, which makes it robust and exquisitely woven. Despite their variations, they are all made of cotton and follow a similar manufacturing technique.?

Must Read: How to Choose the Best Hoodie Material?

What is the Muslin’s Origin?

The history of muslin dates back thousands of years, and it originated in Daca, Bangladesh, which is now known as Dhaka. Since the beginning of human history, muslin has been sold all over the world as a luxury good often valued at the same as gold. However, the reason the muslin got its name was because European traders first saw it in Mosul, Iraq. While muslin was imported from Europe, during British colonial rule, muslin artisans in Bangladesh and India endured harsh treatment and were forced to produce other textiles.

Must Read: The Ultimate Guide to Choosing the Perfect Fabric for Custom Clothing

What are the different Types/Categories of Muslin Fabrics?

Gauze

It is a thin, transparent version of muslin fabric that can be used to treat wounds with a dressing. In addition to being used for clothing, this fabric is also used in the kitchen for filtration purposes.

Mull

Mull is thin and light; it is usually made of viscose, but it can also occasionally be made of muslin cotton and muslin silk fabric. Mull is usually used to examine clothing patterns, give an outfit significant weight and shape, or as an underpinning for dresses.

Swiss Muslin

This type of fabric has a delicate, wispiness-textured appearance. This particular type of muslin fabric is embossed with dots or patterns that are popular choices for summer apparel.

Sheeting

Sheeting has more texture and is thicker than muslin fabrics. Its goal is to produce accessories, apparel, and home goods.

Must Read: What is linen fabric Material?

How Is Fabric Made of Muslin Fabric Material?

One of the most versatile materials, muslin is used in clothing, science, and theater, among other fields. Here are some of the uses for muslin fabric that we have deduced.

- Clothes & Tailoring: Fashion designers frequently test different designs on muslin, which is the most common type used in sewing and clothing design. Even though a different fabric was used to construct the model, the term “muslin” is still used to describe it.

- Quilting, also known as stitching, is the process of sewing together at least three layers of fabric, with muslin fabric being used for the covering of the quilt.

- Home Furnishings: Muslin is a delicate, sheer fabric that is used to create an inviting atmosphere in interior products such as towels, thin bedding, and curtains.

- Cleaning: Because muslin fabrics are known to be multipurpose, they are very helpful when doing household tasks, including cleaning. They are easy to reuse for eco-friendly cleaning techniques and to clean.

- Artworks: Because muslin effectively retains dye, it is useful for scrimmages, decorations, and scenery in theatres. Muslin is a lightweight travel opaque that works well for photographers.

- Cheesemaking: To extract the liquid from cheese curd, home cheesemakers pour frothed milk through a muslin sack.

Key TakeAway

Muslin fabric is soft and lightweight, perfectly known for its breathability, and the soft texture of the fibers, making it a loved fabric by all designers and DIY enthusiasts. Specifically, cotton muslin fabric offers the natural comfort of cotton with an airy feel of muslin fabric – the perfect fabric for creating breezy summer garments and delicate drapery. Be it a simple blouse or an intricate gown, cotton muslin fabric provides a soft, comfortable base for several clothing articles, ensuring style combined with comfort. While constructing any garment, the use of muslin fabric for the making of muslin fabric dress prototypes—before finalizing the design in pricier fabric—surfaces and grows to be an indispensable tool in the fashion industry. On the other hand, those who know what muslin fabric is and realize its value appreciate the contribution it brings to a lightweight, breathable option in clothing and home textiles.

Exploration of the muslin fabric price shows its affordability, making it practical for a wider range of consumers looking for quality materials in their projects. Either for crafts or sewing projects, the price of muslin fabric makes it a cost-saving choice for implementation in a vast range of applications. The cost of muslin is practical whether for creating mock-ups or using it to craft a final piece. In each case for the beginner trying out the basics of sewing or the pro putting together the season’s new collection, muslin is a cost-effective but assured option for bringing visions to life.

The post What fabric is Muslin Fabrics? appeared first on Wings2fashion.

]]>The post What is linen fabric Material? appeared first on Wings2fashion.

]]>In this blog, we will go over everything you need to know about linen fabric — definition, types, properties, and more.

What is linen fabric?

The linen fabric material, made from the flax plant, is mostly for home textiles. Though similar to cotton, it’s fabricated from the stem fibre of the flax plant instead of the dolls around the seeds of the cotton plant.

Linen garments are more favoured in hot, humid climates. Unlike cotton, which tends to retain the moisture it absorbs for long periods, linen dries easily, making it much better at reducing the sensation of heat in overly hot temperatures.

Since the invention of the cotton gin, linen has been gradually losing its lustre because the process of making linen is much more time-consuming and resource-intensive than making cotton.

Must read: India’s Top 10 Clothing Manufacturers

How Is Linen Fabric Made?

Manufacturers of this fibre begin by separating the flax fibres from the woody interior of the flax stems so that the fibres are ready for linen production. In the past, manufacturers would soak the raw flax stalks to do this, while in the present day, manufacturers might use chemicals. These chemicals are washed away prior to spinning the flax fibres into yarn, but the risks are that harmful materials might still remain in the chemically separated flax fibre.

Must Read: CMT vs FPP: Which Method is Best method for Your Brand Manufacture?

1. Cultivation

Flax plants require up to about 100 days to harvest maturity. Flax plants require to be cultivated during the cool months of the year in order to avert crop death due to being unable to withstand heat.

2. Irrigation

Flax seeds are now usually planted by the use of machines. The use of herbicides and tilling usually stops reduced yields in flax crops since flax plants cannot prevent weed infiltration.

3. Harvesting

Flax plants are prepared for harvesting when their stems become yellow and their seeds become brown. While it is possible to harvest flax by hand, in most cases, machinery is used in the process.

4. Identifying Fibres

Post-harvesting, flax stalks are processed through a decorticating machine to remove the seeds and leaves. Manufacturers then extract the soft, woody core from flax’s fibrous outer stalk. This is called retting, and if done without expertise, it could damage the delicate flax fibres that are meant to be woven into fabrics.

5. Disrupting

This is then followed by breaking the decomposed stalks, separating the useful inner fibres from the inner section of the flax stalks and the outer ‘useless’ fibres. This is done through running rollers over the flax stalks and subsequently using rotating paddles to extract the outer ‘useless’ fibres from the stalks.

6. Blending

The inner fibres can now be combed into thin strands because they have been split off from the outer fibres. The fibres will be ready for spinning after they have been combed.

Must Read: 6 Style Tips for Classy and Unique Dressing

7. Spinning

Today, instead of using the foot-powered flax wheel that was traditionally used to spin flax yarn, flax producers use industrial machinery for that purpose. These short, combed fibres are drawn together with tools known as spreaders in order to create flax fibres, and the strings resulting from this process, which are called rovings, are thus ready to be spun.

8. Casting

The yarn, once spun on a spinning frame, is reeled onto a bobbin. The reeling process is required to be carried out in damp, humid conditions to ensure that the flax yarn won’t break, and then the spun yarn is run through a hot water bath in addition to ensuring cohesion.

9. Desiccating

Finally, the now-ready yarn is desiccated by flax manufacturers before being wound into bobbins. The yarn is then prepared for dyeing, processing, and manufacture of textile products such as clothing and household goods.

Must Read: How to Improve your Dressing Style | Women Fashion

What Different Types of Linen Fabric Are There?

1. Damask linen

Produced on a jacquard loom, this delicate linen is so intricate that when finished, the product looks like embroidery. Damask linen is used more on decorative pieces rather than everyday pieces.

2. Plain woven linen

Plain woven linen is so loosely woven that it’s often used in hand towels, linen fabric cotton, and cotton and linen fabric. It’s so tightly woven that it’s very durable with no significant loss of toughness.

Must Read : How much does it cost to manufacture clothing in India?

3. Loose weave linen

This type of linen woven with a loose weave is the least durable linen. However, loose-woven linen is the most absorbent. Common uses are sanitary napkins and reusable diapers.

4. Sheeting linen

Sheeting linen is so closely woven that its surface is soft and doesn’t have a texture. This type of linen is typically used for linen clothing.

Where Is Linen Fabric Produced?

At present, China is the largest linen fabric supplier in the world, as it is with most linen fabric shirts. Yet, many European nations still have an interest in producing fine linen goods, and Ireland, Italy, and Belgium remain the major producers. A relatively large amount of linen is also produced in the United States and used for home goods.

Must Read: What is Spandex Fabric: The Ultimate Guide to Stretch

Key Takeaway

The release of chemicals used in the retting process into nearby ecosystems is the main environmental concern related to the manufacturing of linen fabric material. The most common methods of extracting flax fibres from the woody interior of flax stems are alkali or oxalic acid. Though undoubtedly chemical retting is much faster and more effective than any microbial methods, both alkali and oxalic acid are very poisonous if used in relatively small amounts.

Water-retting flax stems is thus an environmentally preferred option, and water-retting flax fibre is usually necessary for organic certification. However, water retting merely adds to the already high cost of flax, with organic flax remaining too expensive for most consumers.

The post What is linen fabric Material? appeared first on Wings2fashion.

]]>The post How to Reduce Lead Time in Garment Manufacturing appeared first on Wings2fashion.

]]>How to Reduce Lead Time in Garment Manufacturing

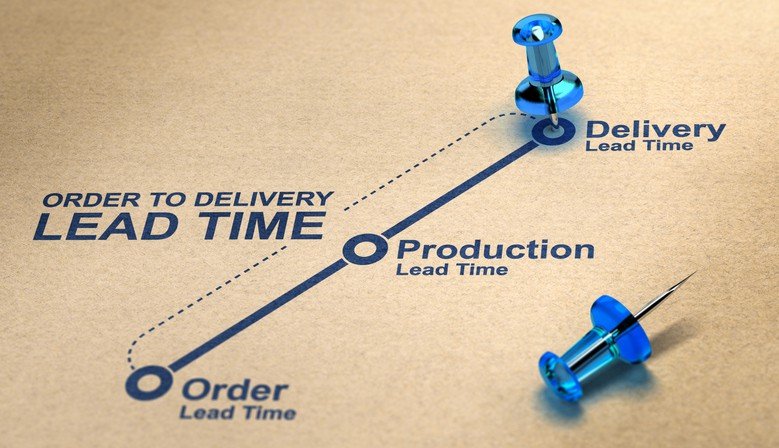

What is lead time in fashion?

Lead time in the fashion industry refers to the total amount of time needed to finish the entire production process of a garment, from the placement of the order to the delivery of the product. This involves a lot of steps, including designing, dying, printing, cutting, sewing, quality checking, and shipping.

The time between placing an order and having the product delivered to the customer is known as the lead time in the garment manufacturing industry. Consumers want their purchases and deliveries to be made quickly, so knowing what lead time is, how to cut it down, and how it affects the customer experience are all valuable insights that can help you grow your company.

Why is a shorter lead time important?

Many companies now inquire as to whether they ought to make a concerted effort to shorten lead times.And the response is unquestionably yes. Although being aware of lead times is beneficial for carefully controlling inventory, our goal should always be to reduce the time spent on product development.

These are some of the causes. Increased adaptability in quickly evolving marketsBeat the oppositionFaster stock replenishment to prevent backorders and stockouts and possible decrease in carrying costs are but a few of the explanations for why you ought to be attempting to shorten Lead Time in Clothing Manufacturing. ?

Must Read: Private Label Clothing Manufacturers: Your Path to Quality Apparel

How to Reduce Lead Times in the Garment Manufacturing Industries:

In the clothing manufacturing industry, shorter lead times can increase productivity and customer satisfaction.

The following list of tips will help shorten Lead Time in Clothing Manufacturing.

1. Put lean manufacturing principles into practice:

The main goals of lean manufacturing are efficiency gains, lead time reduction, and waste elimination. Manufacturers can cut lead times, increase product quality, and increase overall operational efficiency by putting lean principles into practice.

2. Adoption of technology:

All the more successful businesses invest in technology such as computer-aided design (CAD) for pattern-making and cutting, 3D printing for prototypes and custom clothing items, fully implemented CAD (Computer Aided Design) and partially implemented CAM (Computer Aided Manufacturing).

Because CAD designs quickly for various sizes of the same design, it helps achieve shorter at times. By eliminating the need for manual material handling and achieving greater manufacturing speeds and accuracy, CAM also reduces manufacturing time.

Supply chain management is enhanced by the use of RFID (Radio-Frequency Identification) technology for inventory tracking and management. Generally, the need to cut costs and increase efficiency is what drives the adoption of new technologies in the clothing industry.

Must Read: Outfit Ideas To Go Out Partying In Summer

3. Put improvement processes into place:

Manufacturers can pinpoint the problems causing production delays by putting continuous improvement processes into place.We can examine production process data, find appropriate solutions, and put those solutions into action.

4. Shorten setup and changeover times:

These can be a significant cause of manufacturing delays. Reducing the amount of time it takes for production line changeovers requires careful planning regarding the number of machines, labour, fabric, and trims that are required.The setup time can be measured using SMED, a lean manufacturing technology.

5. Enhance production scheduling and planning:

Manufacturers can minimise delays and cut down on the time it takes to produce each product by using an accurate production plan. Every task is guaranteed to be finished on time and in the most effective order with precise planning and scheduling. By putting in place real-time monitoring systems, demand-driven production optimisation, supplier collaboration, and a continuous improvement programme, we can enhance the production process.

6. Enhance supply chain management:

Reducing delays in material sourcing may be made possible by improving supply chain management. The following are some ideas to enhance supply chain administration.

- Build a solid rapport with the supplier.?

- Boost the visibility of the data.?

- Make use of modern technology. streamlining of the route.

- Inventory control.

Must Read: Clothing Manufacturers India: From Tradition to Innovation

Concluding Remarks How to Reduce Lead Time in Garment Manufacturing

Efficiency and customer satisfaction in the apparel industry depend on an understanding of and ability to manage lead time. Careful consideration is needed for the various factors that affect lead time, including supplier location, product complexity, brand size, and fabrication techniques. Apparel Manufacturers should use technology, improve production planning, apply continuous improvement procedures, embrace lean manufacturing principles, and expedite setup and changeover times to cut lead times.?

Furthermore, reducing delays is largely dependent on efficient supply chain management, which includes fostering solid relationships with suppliers and making use of technology.You can increase cells in many different ways by reducing your manufacturing time. You can also save money by optimising your inventory management and avoiding paying to carry stock that you don’t need.

It’s a win-win situation, but to make it work, you’ll need to recognise and manage your late periods.By putting these strategies into practice, Private label Clothing Manufacturers can meet market demands and increase operational efficiency, which will ultimately result in happy customers and profitable enterprises.

Must Read: India’s Top 10 Clothing Manufacturers

The post How to Reduce Lead Time in Garment Manufacturing appeared first on Wings2fashion.

]]>The post Exploring Authentic Lederhosen Types to Celebrate Bavarian Traditions in Style appeared first on Wings2fashion.

]]>Material Based Lederhosen Classification

From the enduring durability of classic leather to the luxurious elegance of suede, Lederhosen can be divided into several categories based on their material:

Embracing Tradition: The Traditional Appeal of Leather Lederhosen

Leather lederhosen is a classic choice because of its durability and ruggedness. It is most commonly used and is quite famous in the Bavarian region. Leather Lederhosen also come in a variety of styles:

- Deerskin Lederhosen: Deerskin Lederhosen is considered the best quality because of its elegant appearance.

- Cowhide Lederhosen: Coming from the hides of cows, cowhide lederhosen offer a thicker leather than deer or elkskin lederhosen.

- Sheepskin Lederhosen: These come from the sheep’s skin and are appreciated for their ease of movement.

Whatever type of leather you choose, ensure it fulfills your specific requirements because everyone has different preferences. There’s no use going for something “ trendy” that doesn’t meet your own needs. So be smart about your buying decisions.

Explore More : What is Garment Fabrication? Lets Explore it in Term of Textile World of Fashion

Sophisticates Style: The Charm of Suede Lederhosen

Although suede lederhosen is less prevalent, it still offers many valuable properties, which makes it a good choice. They have a finer and more delicate appearance and come in various neutral colors, giving them a classy touch.

Modern Twist on Lederhosen : Denim Lederhosen

Contemporary fashion has elevated lederhosen to a modern fashion statement by experimenting with different materials such as denim. If you’re someone who prefers comfort over everything but you also want to dress culturally, we have a solution for you. Your favorite pair of jeans mixed with a spice of Bavarian heritage? What more could you ask?

Length Based Classification

Another fun way to classify lederhosen is based on their length:

Short Lederhosen (Kurze)

As the name suggests, these lederhosen are shorter than average and are typically above the knee. They are an excellent choice for a hotter day. You can pair them up with knee-high socks and traditional German footwear.

Knee-length Lederhosen (Kniebund)

These Bundhosen provide more coverage to the wearer by extending to the knees. These offer the middle ground as they are longer than short lederhosen but shorter than long ones.

Long Lederhosen (Lang)

Long Lederhosen offers the most coverage among all lederhosen by extending to the ankles. These are most suitable for formal occasions and can provide protection in colder climates.

Did you know? The prime thing that differentiates a Lederhosen from a Bundhosen is its length. Bundhosens generally are more extended than Lederhosen.

Explore More : T-Shirt Printing as a Marketing Tool: How to Promote Your Brand

Region Based Lederhosen Types

Region-based lederhosen refers to the difference in stitching patterns (Stichmuster) and styles that occur and are influenced by the area where the men’s lederhosen is made. Sometimes, local flora and fauna are embellished on the lederhosen, while at other times, geometrical patterns are used depending on the preferences of the region and its people.

Bavarian Elegance: The Lederhosen from Bavaria

Bavaria is a state in southeast Germany that is the hub for Oktoberfest celebrations. So naturally, Lederhosen is common in this area. Compared to other regions, the difference these lederhosen have is that the embroidery on Bavarian lederhosen depicts Bavarian culture. For example, depicting edelweiss flowers or alpine landscapes is frequently used as an embellishment in Bavaria.

These lederhosen are used all year round in weddings and celebrations, especially during Oktoberfest. They’re combined with a beautiful feminine dirndl and are the go-to outfit for couples in Bavaria.

Alpine Majesty: The Lederhosen from Austria

lederhosen are referred as “ Gambsbart Lederhosen” in Austria.This name is derived from the gamsbart pin that adorns it, which is locally seen as a sign of masculinity. A gamsbart is a tuft of hair retrieved from chamois ( a type of goat in Europe). These lederhosen reflect the rugged alpine terrain of Austria and are made with durability in mind.

Swiss Style: The Lederhosen from Switzerland

In German-speaking regions of Switzerland, such as Zurich, Bern, and Basle, lederhosen are pretty much everyone’s favorite cultural attire. These German men’s lederhosen are generally simpler in design than their Austrian and Bavarian counterparts. Often adorned with rustic buttons, these buttons symbolize Switzerland’s rustic charm and mountainous landscape.

Tailoring Based lederhosen

lederhosen classified based on their tailoring can be broken down into the following types:

Embroidered Lederhosen

Embroidered lederhosen are very appealing to the eye because they are characterized by skilled artistry of patterns, shapes, and motifs. This unique craftsmanship, featured on flaps or suspenders of the garment, is done by Bavarian locals, and the skill is passed down from generation to generation in Bavaria.

Must Read: 15 Most Expensive Luxury Bags in the World

Plain Lederhosen

If you are more of a minimalist, plain Lederhosen is the perfect choice, as it includes minimal to no embroidery. The main focus of this type of lederhosen is the quality of its leather and its craftsmanship. It’s perfect to wear for any casual outing or even formal events.

Custom Lederhosen

Custom lederhosen are tailored to each person’s preference, and the leather and embroidery can be customized.

Lederhosen through Time: Exploring Modern vs Vintage Lederhosen

Vintage lederhosen are the breeches that preserve the traditional styles of past eras. They come in many different styles and are generally very expensive for their antiquity. The leather of vintage Lederhosen is heavier than that of modern ones. Where modern lederhosen focuses more on innovation and contemporary style, The vintage style prides itself on preserving old traditions.

Did you know? lederhosen are designed to fit snugly but should not be overly tight to remain comfortable for the wearer.

Key Takeaways: Which Lederhosen to Choose?

Each lederhosen has its specialties, which we discussed. Choosing the lederhosen depends entirely on you, as it comes in various styles based on length, tailoring, region, and material. Whether you prefer the vintage or contemporary look, the Lederhosen has several options to fulfill everyone’s preferences!

The post Exploring Authentic Lederhosen Types to Celebrate Bavarian Traditions in Style appeared first on Wings2fashion.

]]>The post What is Garment Fabrication? Lets Explore it in Term of Textile World of Fashion appeared first on Wings2fashion.

]]>Fabrication vs. Manufacturing: Clearing the Confusion

People mostly use the terms “fabrication” and “manufacturing” mutually, but there’s a big difference. Let’s break it down:

Fabrication: Focuses on creating the fabric itself – the fundamental building block of a garment and prints etc.

Manufacturing: After the work of fabrication we turned that fabric into a finished piece of clothing. This includes design, pattern-making, cutting, sewing, finishing, and packaging.

Think of fabrication as the creation of the design, while manufacturing is the art of painting a masterpiece on it.

Explore More : Wings2Fashion: Elevating Your Kurti with Exquisite Embroidery

What is Fabrication? Definition and Examples

Here’s a closer look at fabrication and the key techniques involved:

Definition: Fabrication is the process of converting raw materials (fibers or yarns) into finished fabrics ready for garment construction.

Examples: What is Fabrication work

Weaving: interlinking two types of yarns at right angles to create a fabric. Like the crisp cotton shirts, luxurious silk scarves, or durable denim jeans.

Knitting: In this process of yarn to create a stretchy, textured fabric. Examples include cozy sweaters, comfy t-shirts, or soft leggings.

Dyeing: Adding color to fibers, yarns, or fabrics. This can be done through various methods like natural dyes, reactive dyes, or pigment dyes.

Printing: Applying patterns or designs onto the fabric surface. Examples include floral prints, bold graphics, or classic stripes.

Finishing: Treatments applied to enhance fabric properties like softness, wrinkle-resistance, water-resistance, or stain-resistance.

Explore More : 15 Most Expensive Luxury Bags in the World

What is Fabrication in Research

The choices made during the fabrication process significantly impact your clothes:

Look and Feel: In Fabrication we make a garment’s texture, drape, and overall aesthetic appeal.

Durability: Some fabrics are naturally more durable for everyday wear, while others may be delicate and require special care.

Functionality: Fabrication choices can influence properties like breathability, moisture-wicking, and warmth, affecting a garment’s suitability for different activities or weather conditions.

Sustainability: Textile fabrication can have an environmental impact. Opting for eco-friendly fibers, recycled materials, or low-impact dyeing processes contributes to sustainable fashion.

Steps Involved in Fabricating Garments

Design Development: This stage entails conceptualizing designs either manually or using computer-aided design (CAD) software.

Pattern Making: Patterns are drafted based on the design, serving as templates for cutting fabric pieces.

Fabric Cutting: Fabric is cut according to the patterns, ensuring precision and minimizing wastage.

Assembly: Fabric pieces are stitched together following the designed layout.

Finishing: Final touches such as hemming, pressing, and adding closures are done to complete the garment.

Explore More: What makes USA Brand Clothing stand out?

The Art of Fabrication

After cover topic of what is fabrication work, now we have full process knowledge if Fabrication that how your final clothing design ready to wear when you buy from Stores. Here you are beware of full process of different types of fabric options and technical details of them. Now you have knowledge of clothing when you go for buy as per your styles, need and values.

Wings2fashion is leading Garment manufacture and Supplier is top Garment fabricator in India. We provide all types of service from fabric sourcing to final your design concept ready and live.

FAQs (Frequently Asked Questions)

Is fabrication the same as manufacturing?

While related, fabrication and manufacturing denote distinct processes. Fabrication involves constructing or shaping individual components, while manufacturing encompasses mass production of finished goods.

What are some examples of fabrication in the garment industry?

Fabrication in the garment industry includes cutting, stitching, and assembling fabric pieces to create finished garments.

How does 3D printing revolutionize garment fabrication?

3D printing technology allows for the creation of complex designs and prototypes with precision, reducing material waste and production time.

What are the challenges in fabricating garments?

Challenges include maintaining quality control, managing costs, and meeting tight deadlines amidst production constraints.

What are the future trends in garment fabrication?

Future trends include sustainability initiatives, smart fabrics, and the rise of on-demand manufacturing to meet evolving consumer demands.

The post What is Garment Fabrication? Lets Explore it in Term of Textile World of Fashion appeared first on Wings2fashion.

]]>The post USA Brand Clothing: Top 10 Popular American Brands appeared first on Wings2fashion.

]]>What Makes USA Brand Clothing Stand Out?

American made clothing brands are recognized for their superior quality and craftsmanship. They emphasize durable materials and ethical production processes, ensuring that consumers receive clothing that not only looks good but lasts longer. When you choose USA clothing brands, you’re supporting local economies and fair labor practices.

Benefits of USA Brand Clothing

1. Higher Quality Standards

American clothing brands are renowned for their attention to detail and high-quality materials. This commitment translates into longer-lasting apparel that often withstands the test of time.

2. Support for Fair Labor Practices

Choosing clothing brands for women and men made in the USA means supporting fair labor standards. American laws enforce safe working conditions and fair wages, ensuring that workers are treated ethically.

3. Environmentally Friendly Options

Many best American fashion brands are increasingly adopting sustainable practices, incorporating eco-friendly materials and production processes. By supporting these brands, consumers contribute to minimizing their ecological footprint.

4. Timely Delivery and Availability

American brands prioritize timely delivery, ensuring that customers receive their products on schedule, which enhances customer satisfaction.

American Style: Exploring Iconic and Popular Clothing Brands

American fashion is a blend of classic and modern styles, making it diverse and appealing to various demographics. Here are some of the top 10 American clothing brands that have made a significant impact both locally and globally:

Top 10 Clothing Brands in the USA

- Nike

- Known for innovative sportswear, Nike leads the market with high-performance apparel and footwear. Check out our guide on How To Choose Sportswear That Will Maximize Your Workout? for more tips.

- Levi Strauss & Co.

- The original denim brand, Levi’s is synonymous with quality jeans and casual wear.

- Ralph Lauren

- A symbol of preppy elegance, Ralph Lauren offers timeless styles that embody the American dream.

- Calvin Klein

- Famous for minimalist designs and provocative advertising, Calvin Klein remains a staple in high fashion.

- Tommy Hilfiger

- This brand combines classic American prep with modern twists, appealing to a wide audience.

- GAP

- A go-to for affordable basics, GAP provides versatile options for the entire family.

- Under Armour

- Specializing in performance apparel, Under Armour is a strong contender in the athletic wear market.

- Carhartt

- Initially designed for workwear, Carhartt has become a favorite in streetwear for its durability.

- American Eagle Outfitters

- Targeted at young adults, this brand offers trendy and affordable clothing options.

- Patagonia

- Known for its commitment to sustainability, Patagonia leads in eco-friendly outdoor apparel.

Other Noteworthy American Clothing Brands

In addition to the top 10, several other popular American clothing brands are worth mentioning:

- Guess: Known for trendy denim and stylish designs, particularly among younger consumers.

- Old Navy: Offers family-friendly fashion at budget prices.

- Champion: Known for its comfortable athletic wear that has seen a resurgence in popularity.

- Michael Kors: Provides accessible luxury with a range of handbags and apparel.

- Everlane: Focuses on ethical manufacturing and transparency in pricing.

Trends Shaping American Fashion

American fashion is continuously evolving. Here are some current trends shaping the industry:

- Streetwear Dominance: Comfort and self-expression are key, with hoodies, sneakers, and graphic tees leading the way.

- Sustainability: Consumers prioritize brands that practice ethical manufacturing and use eco-friendly materials. For insights on sustainable practices, check our article on Fashion Trends: Embrace the Spring Summer Season with Style!.

- Inclusivity: There is a growing focus on body positivity and diverse sizing among brands.

- Athleisure: Blurring the lines between workout wear and everyday clothing, athleisure is increasingly popular.

American fashion is a dynamic landscape that reflects both timeless staples and modern trends. Whether you’re looking for quality basics or the latest styles, there’s always an iconic American brand ready to enhance your wardrobe.

For those interested in sourcing apparel, explore our resources on Private Label Clothing Manufacturers in USA, High Fashion Clothing Manufacturers in USA, and Custom Clothing Manufacturers in USA. If you’re looking to expand your brand, learn How to find bulk clothing Manufacturers in USA for competitive options.

The post USA Brand Clothing: Top 10 Popular American Brands appeared first on Wings2fashion.

]]>The post India’s Top 10 Clothing Manufacturers appeared first on Wings2fashion.

]]>

Top 10 Clothing Manufacturers India

- Raymond Ltd. Founded in 1925, Raymond Ltd. is one of the oldest and most respected textile companies in India. They specialize in high-end fabrics and clothing, including formal wear and suits. With a strong focus on innovation and sustainability, Raymond Ltd. has become a leading name in the Indian textile industry.

- Arvind Limited : Arvind Limited is a leading player in the textile industry, with a wide range of products including denim, shirting, knits, and woven fabrics. Their innovative approach to design and manufacturing has helped them to become a global brand, with a presence in over 90 countries.

- Aditya Birla Fashion and Retail Limited : Aditya Birla Fashion and Retail Limited is one of the largest fashion companies in India, with a portfolio of well-known brands such as Allen Solly, Louis Philippe, and Van Heusen. They offer a wide range of products, from casual wear to formal wear, and are known for their quality and style.

- Welspun India Limited : Welspun India Limited is a leading manufacturer of home textiles, including towels, bed sheets, and bathrobes. They have a strong focus on sustainability and ethical manufacturing practices, and are known for their high-quality products.

- Bombay Dyeing : Bombay Dyeing is a household name in India, known for their high-quality bed and bath linen. With a history dating back to 1879, they have become a trusted brand in the Indian textile industry, with a reputation for quality and durability.

- Grasim Industries Limited : Grasim Industries Limited is a leading player in the Indian textile industry, with a range of products including viscose staple fiber, textiles, and chemicals. They are known for their focus on sustainability and ethical manufacturing practices, and have a strong presence in both the domestic and international markets.

- Trident Group : Trident Group is a leading textile company in India, with a range of products including towels, bed linen, and yarns. With a strong focus on quality and innovation, they have become a trusted name in the Indian textile industry.

- Vardhman Textiles Limited : Vardhman Textiles Limited is a leading manufacturer of cotton and blended yarns, with a strong focus on sustainability and ethical manufacturing practices. They have a wide range of products, including apparel, home textiles, and industrial textiles.

- Loyal Textile Mills Limited : Loyal Textile Mills Limited is a leading player in the Indian textile industry, with a range of products including yarns, fabrics, and garments. With a strong focus on innovation and sustainability, they have become a trusted brand in the domestic and international markets.

- Reliance Industries Limited : Reliance Industries Limited is a diversified conglomerate with interests in various industries, including textiles. Their textile division is one of the largest in India, with a wide range of products including yarns, fabrics, and garments. They are known for their focus on innovation and sustainability, and have a strong presence in the domestic and international markets.

India has a rich tradition of textile manufacturing, and these top 10 clothing manufacturers India are leading the way in innovation, sustainability, and quality. Whether you’re looking for high-end formal wear or comfortable casual wear, these companies have something to offer.

In addition to their impressive product lines, these companies are also focused on sustainability and ethical manufacturing practices. They understand the importance of protecting the environment and ensuring fair labor practices, and they are committed to making a positive impact on society.

In conclusion, these top 10 clothing manufacturers in India are some of the best in the world. With their focus on quality, innovation, and sustainability, they are setting the standard for the textile industry. We hope that this article has been informative and helpful in your search for the best clothing manufacturers in India.

The post India’s Top 10 Clothing Manufacturers appeared first on Wings2fashion.

]]>The post How To Choose Sportswear That Will Maximize Your Workout? appeared first on Wings2fashion.

]]>Loose-fitting bottoms and casual t-shirts may appear appealing to beginners but can lead to shortened and uncomfortable workouts. While they may suffice for light exercise, during strenuous routines, they become saturated with perspiration, causing discomfort, reduced focus, and diminished stamina, thereby making the exercise regimen initially more challenging and burdensome. The fabric utilized in casual t-shirts has a propensity to absorb sweat, rendering it non-breathable for the skin, lacking adequate muscle support and hindering proper detoxification processes.

Let Your Workout Decide It For You

To choose perfect fitness clothing & activewear sportswear one must need to keep in sight the workout intensity and type. For instance, cycling and running demands body fit clothes, providing flexibility and breathability, assuring one the proper space and freedom to move, preventing from getting tangled in clothes. Wears like skin-fit leggings, comfortable top wear such as bras, and t-shirts are best suited in such cases. Infrared emitting fabrics and four ways flexible fabrics are the most preferred fabrics that enable an increase in blood circulation and regulating body temperature by evaporating sweat. These are technically crafted for better training, comfort, and support, which may include specialties for specific sports.

Explore Now : Summer 2023 Trends: Women’s Clothing

Specially designed activewear from customized Sportswear manufacturers, such as special t-shirts and bras for women weight lifting provides support for targeted muscle, avoiding injuries and ensuring better muscle recovery. It influences body movement, this affects neural memory of proper muscle movement, resulting in injury-free intensive training, and improved workout capability. One must be aware of the repercussions of injuries while working out, which are surely not limited to workout loss, break in routine, slow recovery, and lessening performance, but may end up in serious permanent disabilities. Proper body support, flexibility, and freedom to move the body in the appropriate form of the workout is one of the major responsibilities and desired features of sportswear. Suitable wear can increase blood flow to the targeted muscle, avoiding fatigue and reducing the risk of cramping.

Must Read: Outfit Ideas To Go Out Partying In Summer

Be Specific About Inner Wears

Similarly, technical inner wears such as sports bras are another important apparel for safe workouts and better body postures. Sports bras are made of flexible fabrics, providing high impact performance, avoiding jerks during jumps, and possible injuries to breasts. Properly fitted and padded bras are better preferred for comfort and support, avoiding sweating and stickiness, enables breathability, and better high effectiveness prevents sagginess or loosening of skin. What must be taken care of while choosing a workout bra is most importantly its the perfect size, comfort, and fabric, which must always be prior to any other factor. Choosing the appropriate band and cup size may seem tricky as it may confuse one between properly fit and too tight when it comes to a sports bra.

It also depends on individual comfort and needs whether one prefers padded or non-padded bras, but suggestively for better safety, pads provide better performance than non-padded ones, especially while weight lifting and intensive workouts. Another important feature of the sports bra to be emphasized is its fabric. While in daily wear, the majority prefers cotton and lose fabrics, sports bras are suggested to be worn in soft and breathable fabric, providing better comfort and sweat evaporating features.

Soaked sweat makes one uncomfortable, it also increases the chances for rashes and other infections caused due to sweat. There’s a range of fabrics used to make sports bras, such as nylon, spandex, polyester, lycra, elastane, and microfiber. The range provides different personal preferences of elasticity and comfort, one may choose according to her body type, as some may tend to sweat more in comparison to others, while some may prefer loose elasticity over more fitted one.

Must Read: Explore Nightwear Manufacturers in Depth: An Exhaustive Overview

Don’t Miss Out On Feets

Another important gear that may not seem to be very essential to be specific about, but impacts workout performance on a major level is a suitable pair of socks. Attention over sports shoes sometimes distracts us from socks and their importance for feet comfort, balance, and muscle support. Similar to technical wear, socks are specific to workout routines and types. For instance, compression socks are best suited for running, skiing, cycling, and intensive workouts. It avoids cramps, supports muscle from excessive stretch and injuries, but is not applicable to yoga.

Yoga poses, and stands require balance and grip to the floor while stretching for better control of the body. Disbalance and excessive stretch may result in muscular as well as more serious internal and external injuries. Yoga socks are particularly designed for yoga application as they are technically crafted with a non-slip grip on the feet and keep legs and toes in place during the workout session. The fabric may be used the same as compression socks, as it is required to avoid getting wet in sweat, provide proper air to inner skin and support feet muscles. One must be aware and specific of the requirements and fabric one may use for workout and casual wear. order today your gym wear with wings2fashion the best sportswear manufacturers in India.

Intra-Workout Recovery

In the list of factors that must be taken care of while choosing sportswear, recovery during workouts. Proper fitness sportswear help in preventing possible muscle injuries and discomfort such as post-workout camps or Delayed Onset Muscle Soreness (DOMS), promoting muscle recovery in between workout sessions. This improved the flow of nutrients and minerals promoting better and fast intra-workout recovery. During workouts, muscles require elasticity to stretch while pumping up, breaking down, and recovery.

To attain this properly, one needs to take care of the 4-way elasticity of clothes being worn. For instance, during lower body workout or hamstring targeted routine, one needs to keep muscle free to pump up, break down, and recover. For such workouts, lowers and yoga pants are highly suggested, with base fabrics of spandex and polyester. These are flexible pants made of breathable fabric, appropriate for muscle support and during workout muscle recovery.?

Explore Now : Clothing Manufacturers India: From Tradition to Innovation

An effective workout session includes various parameters of hydration, muscle movement, and proper application of gears and equipment. Sportswear is defined by personal comfort as well as needs, which impacts the overall hard work of the trainee.

What types of sportswear are made by the sportswear manufacturers in India?

Wings2fashion Sportswear manufacturers make a variety of sportswear such as tracksuits, shorts, leotards, wet suits, helmets, jerseys, sports shoes, etc.

How to Find Sportswear Manufacturers India

If you are looking for Activewear manufacturers India and Sportswear Manufacturers wings2fashion is a leading custom clothing manufacturers and supplier globally.

The post How To Choose Sportswear That Will Maximize Your Workout? appeared first on Wings2fashion.

]]>